FEATURES

Designed for the most demanding digital label finishing workflows, this multi-head blade cutting system delivers unmatched flexibility, speed, and precision.

Engineered with modularity and scalability in mind, this advanced unit uses multiple independent plotting heads to perform complex contour cuts without the need for traditional dies—making it ideal for short to medium runs, frequent job changes, and personalized or variable designs.

Whether you're cutting paper, PET, PP, or specialty films, this system brings next-generation automation and accuracy into your production line—enhancing output, reducing costs, and shortening turnaround times.

Brochure |

Why choose our multi-head plotter cutting system LEO

✔ Adaptability to Various Substrates

✔ Compact Footprint, Complete Workflow

✔ Cost-Effective for Short Runs

✔ No Dies Required

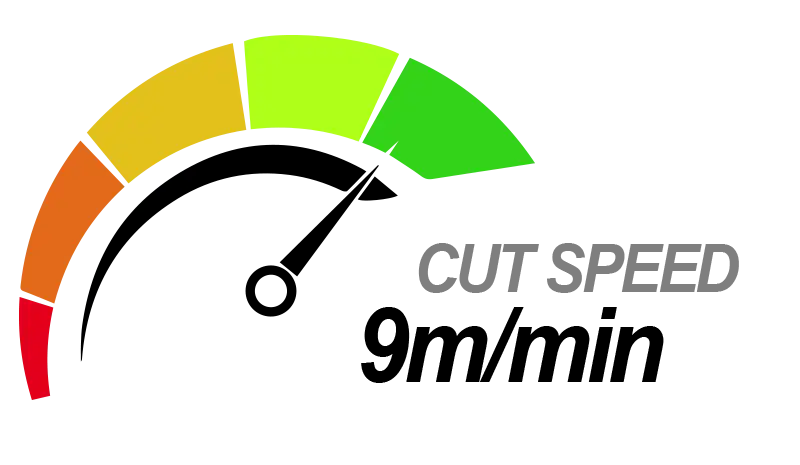

✔ High-Speed Productivity

✔ Precision Cutting

✔ Reduced Downtime

| LEO35PL | |

|---|---|

| Input roll diameter | 500mm (19.68") |

| Finished Roll Diameter | 300mm (11.81") |

| Web Width | up to 350mm (13.78") |

| Maximum Cutting Width | 330mm (13") |

| Maximum Label Length | 500mm (19.68") |

| Cutting Technology | 4 heads drag knife plotter |

| Registration Sensor / Mark | Laser / 4mm x 4mm (0.16" x 0.16") |

| Laminate / Laminate Liner Rewinder | Included / Optional |

| Second Rewinding Shaft | Optional |

| Cut Ability | Printed and unprinted |

| Media Type Allowed | Paper and films |

| Roll core size | Pneumatic 76mm (3") fixed |

| Minimum Slitting Width | 19mm (0.75") |

| Number of slitting blades | up to 8 |

| Power Requirements | 100-240V~1Kw, 50/60Hz |

Brochure

-

-

In a single pass LEO is capable of laminating, die cutting, waste removal, slitting and rewinding finished labels onto new rolls that are ready for application.

Type of cut: Kiss-cut

No material limitless

| MODEL | LENGTH | WIDTH | HEIGHT | WEIGHT |

|---|---|---|---|---|

| LEO35PL | 190cm (74.80") | 88cm (34.64") | 140cm (55.11") | 600kg (1322lb) |

VIDEO